Under the influence of the epidemic in 2020, the growth rate of the smart manufacturing industry has slowed down. However, with the full support of relevant national policies, the development prospects of the smart manufacturing industry are still optimistic.

Intelligent manufacturing has entered a stage of rapid development, showing nine new trends

1. Demand-oriented and pain point focus will guide industrial artificial intelligence from ideal to reality

On the one hand, the application of artificial intelligence technology in the manufacturing industry focuses on industrial intelligent products or solutions for specific industrial pain points. On the other hand, the technology of "sending charcoal in the snow" is more easily accepted by manufacturing companies than industrial intelligence products that are "icing on the cake".

For example, surface quality inspection technology based on machine vision helps improve product quality; or use intelligent CAD based on knowledge graph to improve production efficiency; or use energy distribution based on artificial intelligence to reduce production costs.

2. Industrial big data will become the core of intelligent manufacturing and industrial Internet development

In the development of industrial big data, security will become an important basis for enterprises to make intelligent upgrade decisions. For example, the value of industrial core data, key technology patents and other digital assets to enterprises is accelerating; reducing data security risks, improving system security and data security have become increasingly important reference indicators in the digital transformation and upgrading of enterprises; increasing plant production safety and process safety Imminent.

3、基于大数据的工业智能将带来更多服务型应用场景3. Industrial intelligence based on big data will bring more service-oriented application scenarios

For example, fault diagnosis and predictive maintenance based on industrial data, which are rapidly forming, are typical service-oriented application scenarios. In this service scenario, after processing and storing production line monitoring and historical data, a predictive analysis based on artificial intelligence is performed to give maintenance suggestions to the enterprise and provide real-time warning of production.

4. The equipment state intelligent management system will become a new mode of remote operation and maintenance

The equipment status intelligent management system will become a new model of remote operation and maintenance, and will form a data-centric core, from intelligent collection, intelligent analysis, intelligent diagnosis, intelligent scheduling, automatic commissioning, push solutions, remote support to intelligent inspection, and then enter the new A round of intelligent collection of closed-loop operating modes.

5、工业区块链将服务于数据安全及分布式智能生产网络5. Industrial blockchain will serve data security and distributed intelligent production networks

On the one hand, industrial blockchain technology can provide factories with different security levels of blockchain encryption services, without intermediary transmission of important data between factories, to ensure the encryption security of important production data; on the other hand, with the industrial zone The application of blockchain technology will form a distributed intelligent production network, which will be dominated by the needs of end customers and promote industrial service transformation. Improve enterprise efficiency through integrated and intelligent production. Through standardization and networked production, reduce the production costs of enterprises.

6. Collaborative robots will become the mainstream development direction of industrial robots

At the Shanghai Industrial Fair in 2019, the world's leading robot companies such as Denmark's UR company, Japan's FANUC, Kawasaki, and Germany's Kuka robots launched the latest collaborative robot products on the spot; domestic companies such as Shinsong, Eft, and Festival , Luo Shi, and invited blogs have also released their own collaborative robots. In 2019, at the World Robot Conference, Shanghai Industrial Fair and the World Intelligent Manufacturing Conference, collaborative robots are strongly sought after by domestic and foreign manufacturers, and the future prospects are promising.

7、基于算法的工业智能平台将成为应用场景的重要基石7. Industrial intelligent platform based on algorithm will become an important cornerstone of application scenarios

Different industrial industries have their own unique industry thresholds, and the demand for each industrial scenario in different industries and different companies varies greatly. The path of deep integration of artificial intelligence and manufacturing is to combine information technology with the application of industrial scenes. Modeling, algorithmizing, and coding industrial intelligent algorithm platforms for core processes are oriented to industrial scenarios and can provide convenient development services for the underlying applications.

8. Cloud-side collaboration will become an important technical route for industrial intelligent application products

On the one hand, in the future, the rich cloud business capabilities will be extended to edge nodes to realize the collaboration of sensors, devices, application integration, and image processing; on the other hand, the industry will work together in the cloud and the edge, and the cloud edge will combine to create an industrial brain . The algorithm upgrade will be completed by the cloud.

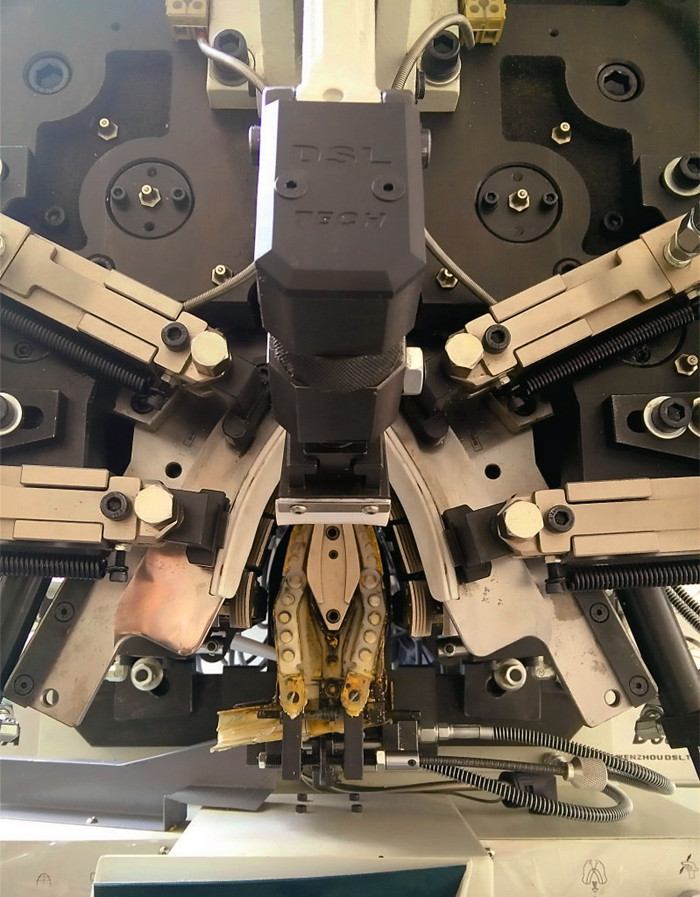

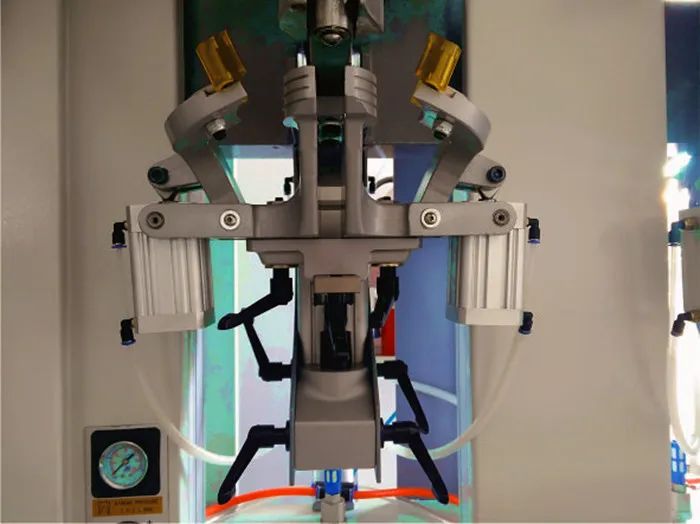

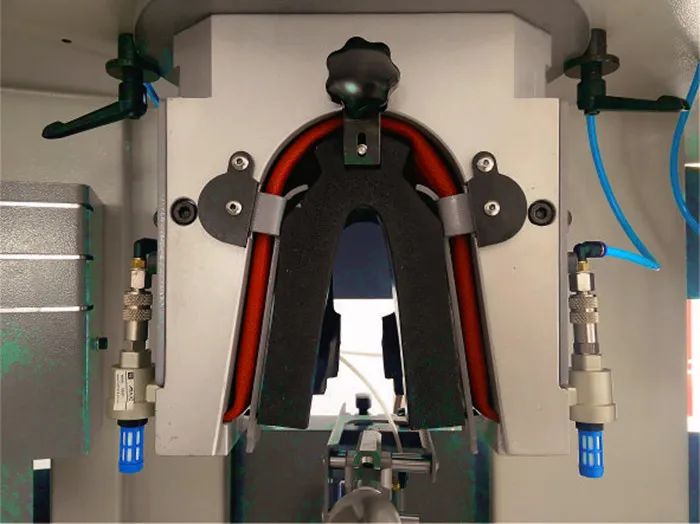

9. The intelligentization of process equipment will become a breakthrough in the transformation and development of the manufacturing industry

In the future, the integration of core process equipment and artificial intelligence to realize the intelligentization of process equipment will become a breakthrough in the transformation and development of the manufacturing industry.

Dapeng adheres to its inner conviction and constantly strives for excellence. It always keeps in mind the corporate mission of "down to earth, setting a good example for the industry, and guiding the healthy development of the shoe industry", constantly strengthening internal cultivation, and serving you with a grateful heart! Choosing Dapeng machines is even more powerful! Choosing Dapeng is to choose a practical, responsible and honest equipment supplier!

Official website: http://www.rocmachine.com

Order Advisory Hotline: 13924236998 (WeChat same number)

Our main products: shoe factory assembly line, three-dimensional assembly line, nail heel machine, heel shaping machine, shoe making factory equipment, front helper, rear helper, peeling machine, Italian shoe machine, Texlon shoe machine